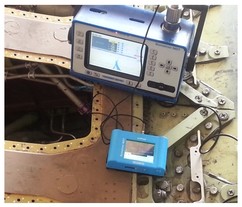

ISONIC 16:16

Very Powerful Superior Performance Extremely Portable Smart Phased Array Ultrasonic Flaw Detector and Recorder

with Conventional UT and TOFD Channels

- Flaw Detection and Thickness / Corrosion Mapping

- True-To-Geometry Volume Overlay and 3D Coverage and Imaging

- TOFD

- CHIME and SRGW - Short Range Guided Wave

- Operating 1 or 2 PA Probes Simultaneously: No External Splitter Required

- and much more...

Phased Array (PA) Modality:

- Fully parallel 32:32 PA electronics expandable to 64:64 / 128:128 functionality

- 1 or 2 PA probe terminals: 1 X 32:32 only or 1 X 32:32 / 2 X 16:16 - switchable: there is no external splitter required for operating 2 PA probes simultaneously

- Ability of work with PA probes carrying up to 64 and 128 elements

- Independently adjustable emitting and receiving aperture with parallel firing, A/D conversion, and on-the-fly real time digital phasing

- Phased array pulser receiver with image guided ray tracing / scan plan designer for the numerous types of simple and complex geometry welds, shafts, bolts, spindles, composite profiles, and the like

- 8192 independently adjustable focal laws

- Bi-polar square wave initial pulse: up to 300 Vpp / 100 dB analogue gain / 0.2...25 MHz bandpass / 16 bit 100 MHz ADC / 32 taps smoothly tunable digital filter

- Regular and volume overlay B-Scan / Sector Scan (S-Scan) / Horizontal Plane S-Scan (CB-Scan) coverage accompanied with all-codes-compliant A-Scan based evaluation

- Multigroup coverage composed of several cross-sectional B- and S-Scans

- Strip Chart

- Single group and multigroup Top (C-Scan), Side, End View imaging formed through encoded / time-based line scanning, 3D-Viewer

- Single side / both sides weld coverage with use of one PA probe / pair of PA probes

- TOFD Map out of a pair of PA probes

- Top (C-Scan), Side, End View imaging formed through encoded XY- scanning, 3D-Viewer

- Built-in automatic coupling monitor and lamination checker for wedged probes

- Equalized cross sectional coverage sensitivity: TCG-independent gain per focal law adjustment providing pure angle gain compensation for S-Scan, etc

- DAC, TCG

- Dynamic Focusing

- FMC, TFM, Back Diffraction Technique with / without and Mode Conversion

- Processing of diffracted and mode converted signals for defects sizing and pattern recognition

- Operating 2D-array probes

- 100% raw data capturing

- Automatic alarming defects / generating of editable defects list upon scanning completed

- Advanced defects sizing and pattern recognition utilities

Conventional UT and TOFD:

- 1 or 2 channels

- Single / dual modes of pulsing/receiving for every channel

- Bi-polar square wave initial pulse: up to 300 Vpp / 100 dB analogue gain / 0.2...25 MHz bandpass / 16 bit 100 MHz ADC / 32 taps smoothly tunable digital filter

- Regular A-Scan

- Thickness B-Scan

- True-to-Geometry flaw detection B-Scan – straight / angle beam probes

- CB-Scan

- TOFD

- Strip Chart and Stripped C-Scan

- Parallel or sequential pulsing/receiving and A/D conversion

- DAC, DGS, TCG

- FFT signal analysis

- 100% raw data capturing

General:

- Intuitive User Interface

- Single and multi-axis encoder connection

- Comprehensive postprocessing and data reporting toolkit

- Remote control and data capturing with use of a regualr PC with no need in special software

- No intake air / no cooling IP 65 light rugged case

- Sealed all-functional keyboard and mouse

- 6.5” bright touch screen

- Ethernet, USB, sVGA terminals

Contact form

- Husova 353/6, 250 01 Brandýs nad Labem

- +420 311 249 523

- info@testima.eu

© 2025 TESTIMA, spol. s. r.o.

Created by eBRÁNA s.r.o. | Powered by CMS WebArchitect | SEO a internetový marketing